Refrigerated Air Dryers

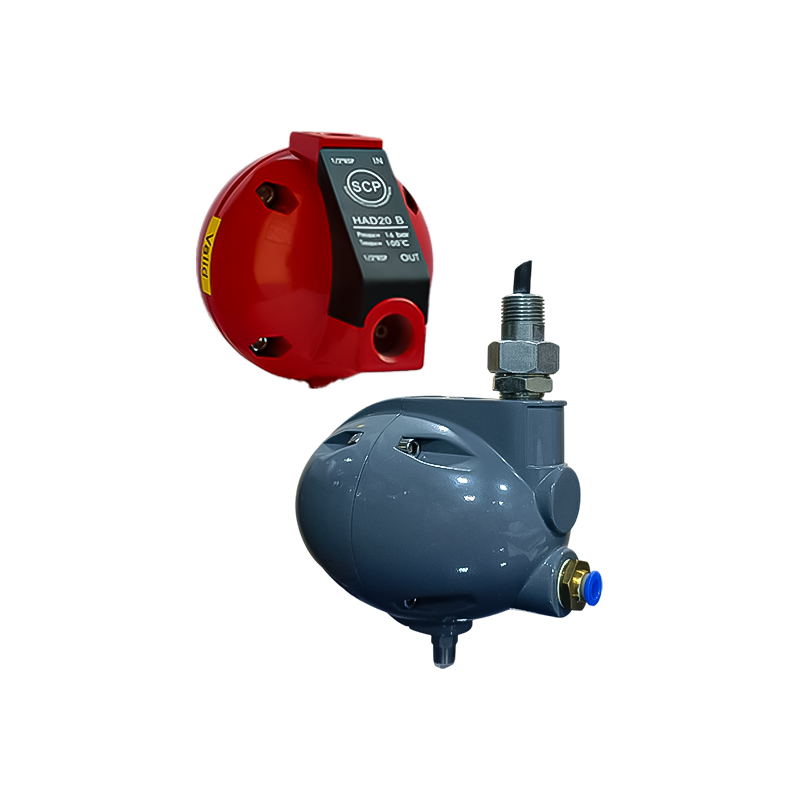

The Annair Platinumstar Series refrigerated compressed air dryers are specifically engineered for high-pressure applications up to 40 bar. These dryers feature heavy-duty, high-thickness copper co-axial tube evaporators, designed using premium-grade copper tubing to ensure exceptional durability and superior heat transfer efficiency.

Built to meet the demands of intensive industrial operations, the Platinumstar Series is ideally suited for applications such as:

• PET blow moulding

• Laser cutting machines

• High-pressure air testing systems

With robust construction and advanced thermal performance, the Platinumstar Series delivers reliable, long-lasting operation in high-pressure environments.

Salient Features

1. High-Pressure Capability up to 40 Bar

Specially designed to perform reliably under high-pressure conditions, ideal for demanding industrial applications.

2. Heavy-Duty Co-axial Copper Tube Heat Exchanger

Built with industry-best, high-thickness copper tubes to ensure maximum durability and enhanced heat transfer efficiency.

3. Application-Specific Design

Tailored for high-pressure operations such as PET blow molding, laser cutting machines, and compressed air testing systems.

4. Robust Construction for Harsh Environments

Engineered to withstand extreme operating conditions while maintaining consistent performance.

5. Efficient Refrigeration System

Utilizes eco-friendly refrigerants and optimized components for energy-efficient operation and minimal power consumption.

6. Hot Gas Bypass Valve for Defrosting

Ensures smooth operation by preventing evaporator coil freezing during low load or fluctuating conditions.

7. Low Pressure Drop Design

Maintains airflow integrity and system efficiency without compromising on performance.

8. Digital Display for Temperature and Status Monitoring

Enables real-time system diagnostics and easy performance tracking.

Send Message